waterproof tatami

Tatami materials for the shower — enjoy a refreshing, beautiful shower

Safety

- These mats are hygienic and prevent the occurrence of mites and mold.

- The mat covers are compliant with the Food Sanitation Act and deemed safe.

- They produce no toxic gases even in the case of when burned.

- They can be safely used in nursing environments, with children, the elderly and those suffering from allergies.

- They are optimal for highly air tight homes.

- Only carefully-selected raw materials sourced in Japan are used to manufacture this product in Japan.

Durability

- They have been developed for institutional purposes and are extremely strong, tough and long-lasting.

- They are difficult to scuff and can be wiped using a damp cloth, making cleaning easy.

- They are resilient against humidity and warping.

- They do not fade in the sun, and no color variation will occur when one mat is swapped out for another in the future.

- The best form of natural soft rush straw mats is recreated to provide these mats with longevity.

- They have 40 times the wear and tear resistance of a natural soft rush straw mat.

- They are water repellent, and any spilled drinks or food can be wiped up easily with no stain remaining.

Stylish and comfortable

- They have a beautiful appearance and provide an air of luxury.

- There is a rich variety of colors that can be matched with Western or Japanese décor.

- The modern Japanese design can go with Western or Japanese furniture.

- They have a natural texture with little shine.

- Despite being thin mats, they offer a surprising amount of cushion.

- They are made of materials and structured in a way that’s easy on skin making them comfortable in any season.

- They feel good under the feet and to the hands, and are smooth to the touch in summer, but not cold in the winter.

- They are thin mats, and don’t require any adjustments in floor height to be installed.

- They also allow wheelchair-accessible casing beads to be easily installed.

- Rich experience installing over 100 thousand mats annually

- Wide-variety of deliveries to ryokans and hotels (over 7,500 locations)

- Wide-variety of deliveries to kindergartens, nursery schools and nursing homes (over 5,000 locations)

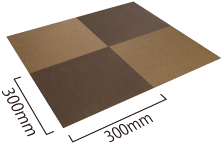

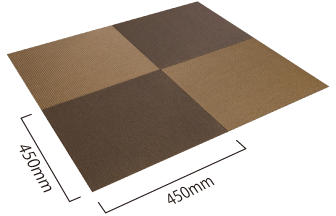

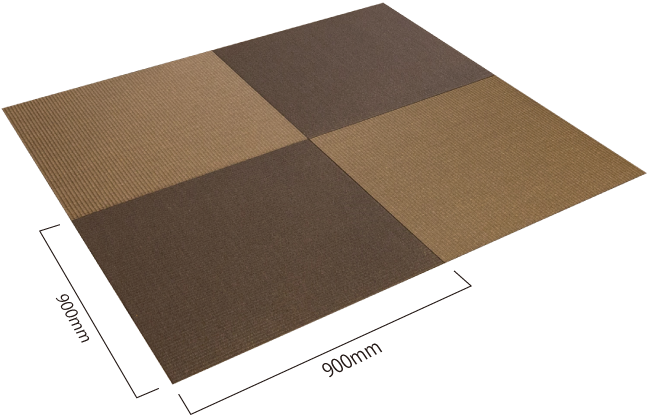

Size variation

300mm x 300mm Thickness of 3mm (Wheelchair-accessible type) Thickness of 5mm (Cushioned type) |

450mm x 450mm Thickness of 3mm (Wheelchair-accessible type) Thickness of 5mm (Cushioned type) |

900mm x 900mm Thickness of 3mm (Wheelchair-accessible type) Thickness of 5mm (Cushioned type) |

Specifications

Cover materials: Polypropylene, calcium carbonate

Base material: Polyester

Underside material: Absorbent acrylic

Special characteristics

Does not fray when cut (patented)

Flame retardant

| Patent number | #6829455 #5978412 |

| Flameproof capacity test number | E1160168 (3mm) E1160204 (5mm) |

Exempted from public notice (construction material not containing formaldehyde)

Physical properties

Formaldehyde emission test |

JIS A1901:2015 (Small chamber test) | Chemicals Evaluation and Research Institute, Japan | |

| Chemical analyzed | Atmospheric concentration | Emission speed |

|---|---|---|

| Formaldehyde | < 3㎍/m3 | < 3㎍/m2 |

Evaluation results: Atmospheric concentration and emission speed are within performance standards, and product ranked F☆☆☆☆ equivalent.

Wear and tear resistance test |

JIS A1453 Material mass change measured with wear test on construction materials and construction components (abrasive paper test) Test load: 5.20N Rotation: 500 rotations; 1,000 rotations |

Japan Testing Center for Construction Materials | |

| Units | TARTEC | General plastic floor sheet | |

|---|---|---|---|

| Wear mass | g/500 times | 0.168g | |

| g/1000 times | 0.294g | 0.5g |

Slip test |

JIS A1454 (Polymer type flooring material test) 17 Slip test | Japan Testing Center for Construction Materials | |

| Slip surface | Test direction | Maximum pull load (N) | Slip resistance coefficient |

|---|---|---|---|

| Rubber sheet | vertically (along tatami weaving) | 550 Pmax | 0.70 C.S.R |

| laterally (perpendicular to tatami weaving) | 586 Pmax | 0.75 C.S.R | |

| Socks | vertically (along tatami weaving) | 280 Pmax | 0.36 C.S.R |

| laterally (perpendicular to tatami weaving) | 332 Pmax | 0.42 C.S.R |

Sunlight resistance test |

JIS L0842 (Test of color durability against UV ray carbon arc lamp) | Chemicals Evaluation and Research Institute, Japan | |

| Test material | Natural tatami cover | TARTEC | |

|---|---|---|---|

| Color change (gradation) | After 50 hours exposure | 2 (Somewhat of a color change) | 5 (No color change) |

| After 100 hours exposure | 1 (Significant color change) | 5 (No color change) |

Test of electrostatic properties |

JIS A1455 | Kaken Test Center | |

| U value | 2.0 Grade III (U value 1.2—3.2 Little static electricity produced, and of a standard where static electricity can be prevented) |

|---|